Story originally published in Northwestern Office for Research Magazine

Walking through campus, Justin Notestein envisions solar fuel where others see only shadows. He’s looking to bring the sun down to earth in a new way that could help power cars and illuminate communities.

“Nature has provided a perfect example — in photosynthesis — for turning sunlight into energy,” says Notestein, professor of chemical and biological engineering. “One of the challenges for Northwestern’s Solar Fuels Institute (SOFI) is to hyper-localize this artificial process by engineering a clean fuel source for individual homes.”

SOFI’s “artificial tree” is a modular system that uses a renewable energy source — the sun — to help capture carbon dioxide in the air and convert it into methanol.

“As currently practiced, the CO2 to methanol reaction is exactly the type of process you would never want to put in your garage,” says Notestein. “The required catalyst is extremely sensitive, and presents an engineering challenge to make it practical. Our team is exploring new materials that we feel will be more robust and allow us to operate at lower, safer pressures.”

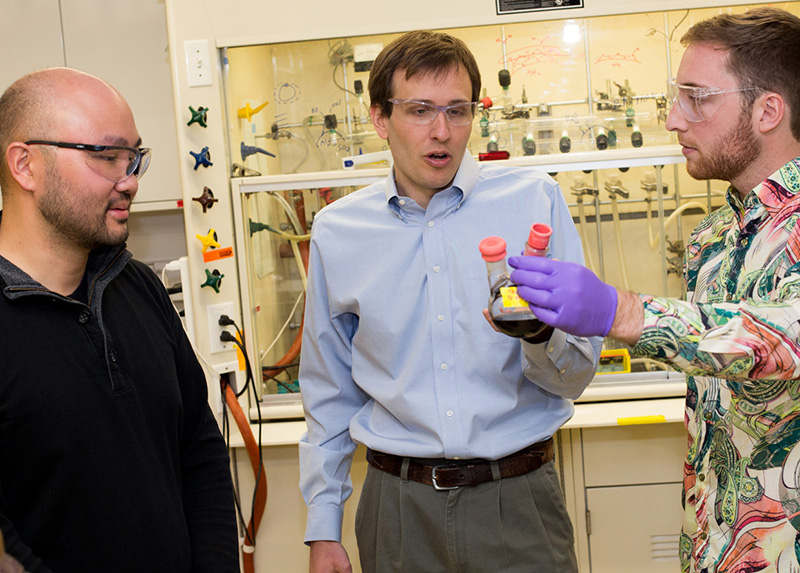

This spring, Notestein and first-year graduate student Alex Grant started work on the initial portion of a four-phase Demo Project that will result in SOFI’s first prototype. Notestein’s lab is developing a small-scale carbon dioxide to methanol reactor that will anchor the project.

Carbon-neutral methanol attracted SOFI’s interest, in part, because of the substance’s flexibility. Methanol is already a proven drop-in fuel for internal combustion engines. In fact, gasoline in China often features a blend of methanol, similar to how ethanol is a frequent additive in the United States.

Dick Co, SOFI managing director, began talking with Notestein and Grant about the final conversion in a functional solar fuel generator about six months ago. The project’s modular nature will allow elements in each phase of the prototype to evolve, merge, or be replaced by new breakthrough technologies over time.

“Our research is focused on this critical end component — the chemical conversion of CO2 to methanol,” says Grant. “Ultimately, our module will be built upon in subsequent phases and the resulting system will maintain an ability to make energy dense fuels cheaply from carbon waste.”

SOFI launched in 2011 as a global research consortium of universities, industry members, and government labs — including Argonne National Laboratory — committed to developing and commercializing a liquid solar fuel. The Demo Project relies on solar energy to generate the electrical and thermal energy needed to drive water electrolysis for renewable hydrogen, direct air capture of CO2, and ultimately methanol production.

“Our vision is for distributed energy generation and storage, in the form of a liquid hydrocarbon,” Co says. “This device, perhaps the size of a washing machine, would take carbon dioxide out of the air, combine it with water, and convert collected solar energy into a liquid fuel. We’d effectively be turning your garage into a pumping station while bypassing the drilling for oil, refining, and transporting the fuel parts of today’s fossil fuel process.”

Rather than take a catalyst “off the shelf” and run it as a miniaturized version of existing chemical plants, Notestein and Grant have identified several materials that might be optimized for small-scale use.

“This research, like many of the most interesting projects in my group, is driven by the students,” says Notestein. “We’re really a design group, so the goal is to make new materials for specific applications or take an existing material and drive it in a totally new direction.”

The remaining phases of the Demo Project will begin during the next year at Northwestern, starting with hydrogen generation from water, then incorporation of solar power, and finally direct air capture of CO2. Completion of the next three phases will supply Notestein and Grant’s reactor with renewable feedstock (hydrogen and CO2) and power, allowing the Demo Project to be truly carbon-neutral.

“There are already ways to complete the reactions in each of the four phases that make up our Demo Project,” says Co. “By optimizing each — beginning with a catalyst designed in the Notestein lab — and keeping an eye on systems integration, we can make solar fuel a reality in the near future and provide the community a platform to collaborate and continually improve upon.”