Catalysis, a science focused on improving the efficiency of chemical reactions, has a profound impact on the energy and environmental footprint of industrial and consumer products—from plastics to pharmaceuticals, solvents to soap, and fuels to food. Many of these reactions require large amounts of energy to initiate or maintain them. For example, the synthesis of ammonia, which is required for industrial fertilizer production, accounts for approximately one to two percent of the world's energy supply. That is the equivalent of more than twice the average amount of energy consumed in Australia per year. Designing new catalysts for this and many other processes has enormous implications for global energy consumption.

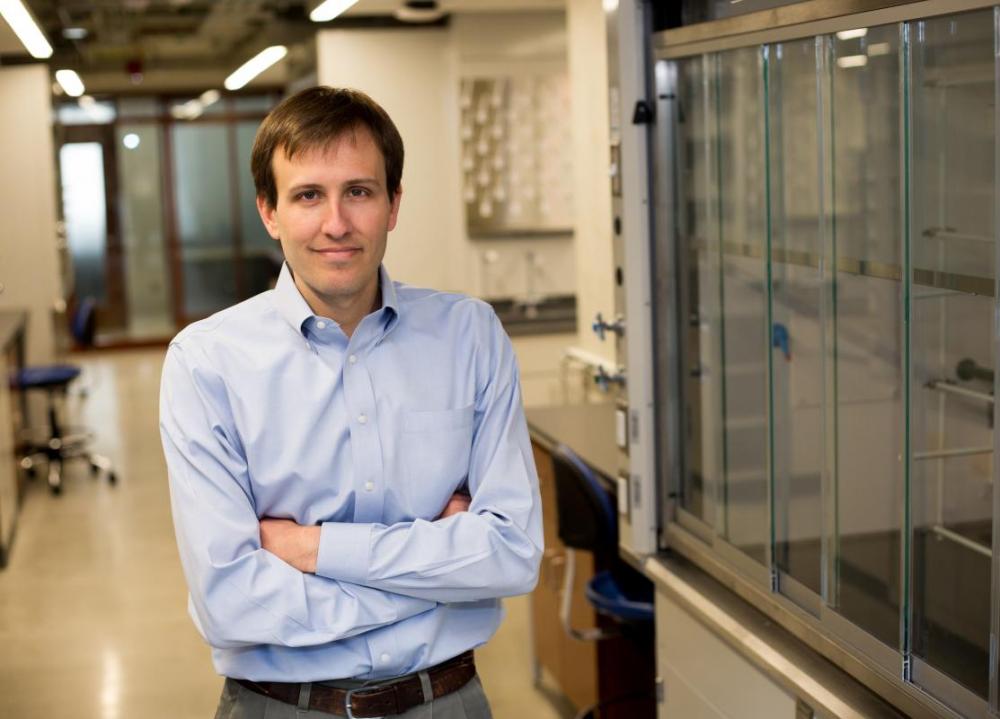

The Institute for Sustainability and Energy at Northwestern (ISEN) recently spoke with Justin Notestein, Associate Professor of Chemical and Biological Engineering at Northwestern University. Notestein is exploring new frontiers in catalysis, developing unprecedented materials for application in largescale chemical engineering.

ISEN: How did you end up at Northwestern, and what brought you here?

Universities usually house catalysis in their chemistry or chemical engineering departments, which is really limiting. At Northwestern, there is catalysis research going on across multiple disciplines, and we're therefore able to leverage everyone’s expertise. The amount of institutional support and team science that Northwestern offers through the Center for Catalysis and Surface Science is incredibly unique.

In many other places, chemists, chemical engineers, and materials scientists speak different scientific languages and may have different goals. But at Northwestern, we’re all “bilingual,” and that comes from working together for so long. We’ve even formalized this culture over the last few years in our CleanCat Core Facility for clean energy catalysis.

In many other places, chemists, chemical engineers, and materials scientists speak different scientific languages and may have different goals. But at Northwestern, we’re all “bilingual,” and that comes from working together for so long.

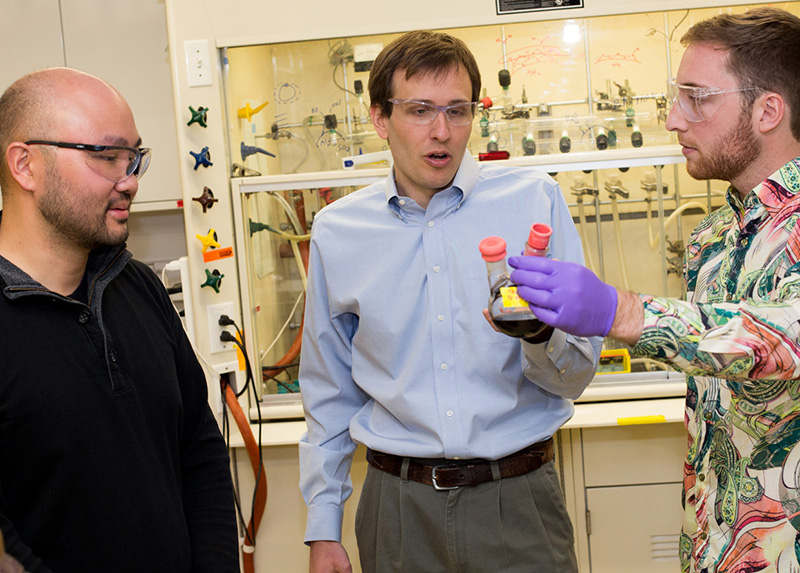

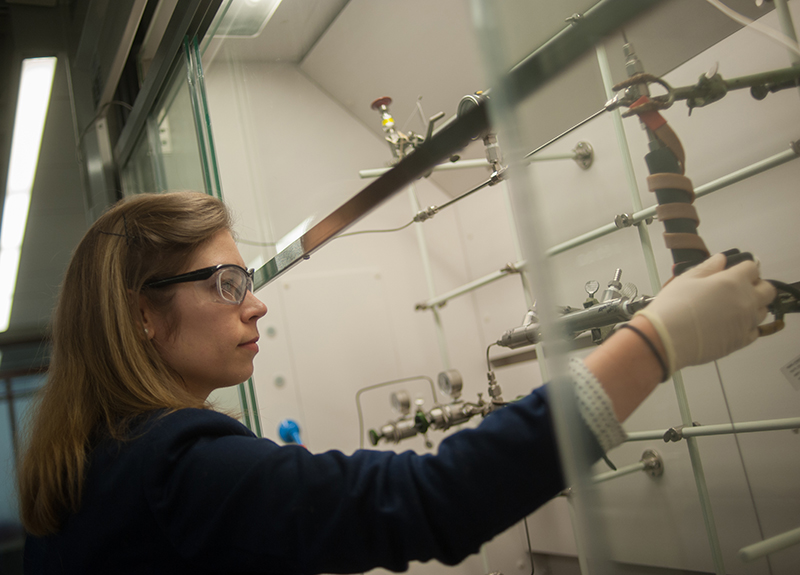

I’m trained as a chemical engineer, which means that I’m trying to aim for relevance to largescale chemical engineering processes when I build new materials in the lab. When it comes to developing materials, I enjoy being involved in the entire process from start to finish. That means that I start by developing a new material, then I test it under real-world scenarios and characterize its structure and properties. At the end of the process, I try to close the loop and generate a finalized, next-generation material. My lab at Northwestern looks like a cross between a chemical engineering lab, a reaction engineering lab, and a chemistry lab.

What types of materials do you work with?

Our research group has a strong background in oxide catalysts, which are really robust when it comes to industrial chemistry. Many of these materials will last for ten years or more under pretty strenuous conditions. We’re dealing with substances like iron oxides and titanium oxides—which are essentially rust and white paint—and are using them in many types of catalytic reactions. These are abundant elements, and they’re incredibly cheap when compared to materials that use precious metals, for example. The fact that someone could use our catalysts without deliberating over the cost when considering whether or not to carry out a chemical reaction is a game changer—especially at the largescale, industrial level.

How can you use these sorts of oxides as catalysts?

Oxides work really well for certain types of reactions when they are made in the right way. A classic example of a good oxide catalyst is titania on silica. When you create very small patches of titanium oxides (or even single titanium atoms) on silicon dioxide, you get a good catalyst for many reactions with, say, hydrogen peroxide. One reaction that uses this catalyst is the synthesis of propylene epoxide, which is used to make de-icing fluid or antifreeze. This and similar chemical compounds are also made into molecular structures that are used in a lot of applications, like forming part of foam cushions. My favorite example is that it shows up in some cheap beers, where it acts as a viscosity modifier, making the drink taste creamier.

We’ve been pushing the envelope for what you can do with these oxide materials—trying to use them as replacements for expensive precious-metal catalysts, for instance. We were working with Toyota on automobile tailpipe catalysts, which are currently a costly mixture of platinum, palladium, and rhodium. All of these precious metals are necessary to neutralize the main exhaust pollutants from the car—carbon monoxide, unburned hydrocarbons, nitric oxide, and nitrogen dioxide. The process is incredibly challenging because you’re trying to simultaneously deal with very different chemistries and all within the confines of your car’s exhaust system. We’re trying to replace the precious metals with cheaper catalysts that will do the job just as well. We’ve had some successes, including academic papers and a patent.

What projects are you currently working on that you find exciting?

In addition to Toyota, we’ve had a long-running partnership with the Dow Chemical company in several areas of research. One area is oxidation catalysis. The current ways to manufacture many chemical compounds are highly inefficient, which also makes them costly and leads to some nasty byproducts that need to be carefully disposed of. We’re trying to improve these processes, which simultaneously makes them cheaper and more sustainable.

Second, we’re working with Dow to change the way they produce some of the compounds that go into the polyurethanes used in foam padding and insulation, and the acrylics that are typically used in clear plastic sheeting and coatings. The current manufacturing processes aren’t exactly benign, and there are growing markets for these materials, creating opportunities for new types of production facilities. We’re developing catalysts that are more selective, facilitate reactions at lower pressures (meaning lower energy usage), or can use new chemicals as starting materials. The great thing about these projects is that designing a better catalyst leads to a better chemical reactor, which then leads to a better industrial manufacturing process. Our work is really at the heart of the chemical industry.

What discoveries have you made that you hope industry will widely adopt?

I’m doing a lot of work with Kimberly Gray [Department Chair and Professor of Civil & Environmental Engineering at Northwestern] on photocatalysis—processes that use light and a catalytic material to activate chemical reactions. In the past, we’ve used photocatalysis to perform selective oxidation and reduction reactions, and she is an expert in using photocatalysis to convert CO2 into potential fuels. We’re currently learning to use photocatalysis to generate hydrogen peroxide, which is an extremely useful reactant for making other molecules. Essentially, we use air and sunlight to create the hydrogen peroxide, and we couple it with another process in the same reactor which then scavenges that peroxide and uses it to make another chemical in a very selective fashion. So, we’re using light and air to replace a process that would normally require direct addition of hydrogen peroxide.

Not only could our process be a lot cheaper than current methods, but it would also avoid the need to transport industrial-strength hydrogen peroxide, which can react violently when it comes into contact with many organics. Traditionally, when you need to transport hydrogen peroxide, you might have to dilute it with water when it leaves Point A and then re-concentrate it when it arrives at Point B. This all takes a tremendous amount of energy. Even if you avoid this process by producing the chemical on-site, traditional production methods can only be carried out profitably at very large scale, which is limiting.

Plus, traditional synthesis of hydrogen peroxide still produces a lot of harmful waste products. We think that we can make it simply by using air and light, and our methods could allow for cost-effective, small-scale production. We’d love to see these discoveries put into practice somewhere.

Why is adoption of these sorts of discoveries not more widespread?

First, the chemical industry doesn’t have a lot of experience doing photocatalysis. Industrial chemistry occurs in large steel tanks, not the glass containers you see in a chemistry lab, and the engineering isn’t as well-developed for light-driven reactions. Another reason is that largescale chemical processing is an extraordinarily risk-averse field. This is partly due to cost. Some of these processing plants cost several billion dollars to build, and you want them to last a long time. It’s also a safety issue. You need these processes and machinery to run reliably. If you don’t know what you’re doing and can’t run these things safely, people can get hurt.

What is it like for Northwestern students to be working on these types of projects?

I currently have about a dozen PhD students who are doing their thesis research in my laboratory. They’ve cultivated fantastic personal relationships with industry partners which can have some advantages when looking for jobs because they understand how industry works. At the end of the day, a lot of the catalysis research that goes on in industry isn’t that different from the types of things we’re doing in my lab at Northwestern.

Photo by Eileen Molony