Jung Woo “Ted” Seo accelerates lithium ion battery performance for extreme conditions

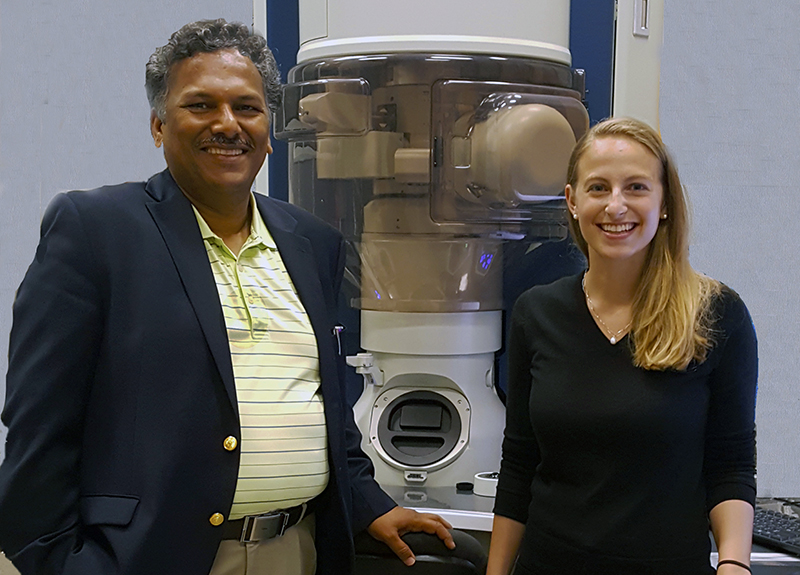

Jung Woo “Ted” Seo (BS ’09, PhD ’16), postdoctoral researcher in the Hersam Research Group at Northwestern University, is bridging laboratory research and industry scale work as a part of the Chain Reaction Innovations (CRI) program of the Department of Energy’s (DOE) Argonne National Laboratory. This spring, Seo joins five entrepreneurs selected from a highly competitive national application process to join the second cohort of the CRI program.

During a two-year term beginning this June, Seo will receive support through fellowship funding that covers salary, benefits, and use of the Materials Engineering Research Facility (MERF) at Argonne. He will also receive support to develop business strategies, conduct market research, and find long-term financing and potential commercial partners.

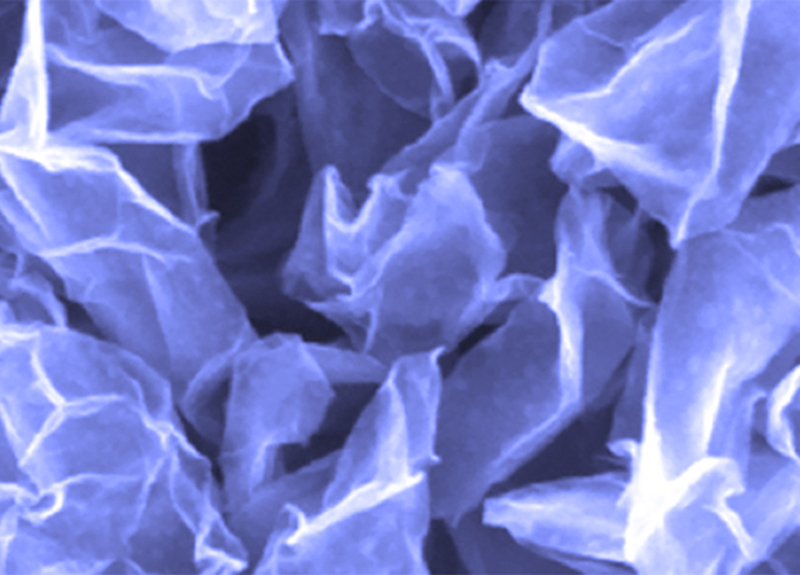

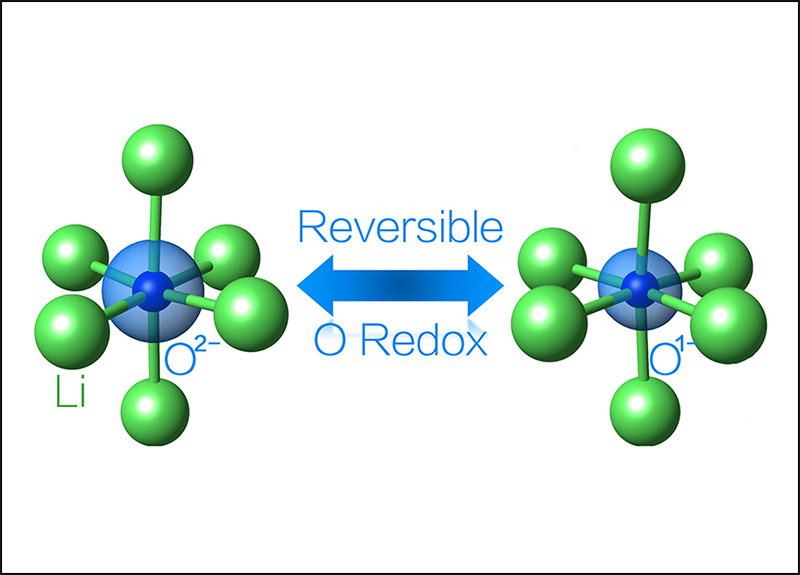

Seo’s focus is the development of a graphene based conformal coating that provides a chemical layer of protection for electrode particles that also facilitate fast charge transport in a lithium ion battery. The technology was born through the Hersam Research Group, led by Walter P. Murphy Professor of Materials Science and Engineering Mark Hersam and funded by Exelon, the DOE, and Northwestern’s Innovation and New Ventures Office (INVO). The coating allows the nanoscale sized electrodes to excel in challenging conditions that require extremely fast discharging rates, such as in temperatures near -20 degrees C, or in high altitudes. Otherwise, batteries will take much longer to charge and may fail prematurely. According to research published by the Hersam Group, the battery performance degradation with their new technology is lower than 15 percent while their conventional control samples showed capacity degradation of 30 to 40 percent.

“Argonne is a world renowned facility for prototyping and testing emerging lithium ion battery technologies, and the MERF is focused on scaling production of these technologies to make them viable for adoption by industry,” noted Seo. “The expansive set of instruments, knowledge and expertise is what really attracted me to the [CRI] program,” he explained. In addition, “The resources of the Hersam Lab will be fully utilized to reach the milestones of the program.”

As a part of the CRI program, Seo aims to fabricate an industry-scale pouch cell prototype while maintaining the performance level seen in the lab at Northwestern, and to build industry relationships with potential clients or end-users.

“The CRI program presents a clear pathway for accelerating the commercialization of the lithium-ion battery technology from our laboratory,” said Hersam, who is also a professor of chemistry in the Weinberg College of Arts and Sciences, professor of medicine at the Northwestern University Feinberg School of Medicine, and director of Northwestern’s Materials Research Center.

The conformal coating has positive implications for a better battery experience across a wide spectrum of possible uses. For example, during a bitter Chicago winter, a vehicle would require less energy to warm up its battery prior to use; or at a high altitude a drone would be able to rise more quickly into the air to fulfill photography or military needs.

Eventually, Seo hopes the technology will also improve microgrid functionality, allowing for smoother electrical operation during power outages or surges. Looking at the big picture, microgrids may also power charging stations for battery powered vehicles.

The partnership is the newest collaboration between Argonne and Northwestern University, who have a longstanding working relationship through other ventures including the Institute for Sustainability and Energy at Northwestern (ISEN) and the Northwestern Argonne Institute of Science and Engineering (NAISE).

Exelon, in a partnership managed by ISEN, funded research associated with this advanced technology as has the DOE and INVO.

Photo: Argonne National Laboratory

Article Updated July 9, 2018