Four Northwestern entrepreneurs bring sustainability and energy solutions to market

by Jim Dallke

As the world has continued to move toward clean energy, so has Northwestern’s materials science program, which is increasingly focused on sustainable materials design. The University has helped launch several companies with the goal of creating innovative energy solutions by designing and developing better materials with less energetic requirements. By bringing innovative materials to the market, these startups are creating disruptive technologies for electric car makers, produce shippers, battery manufacturers, and more.

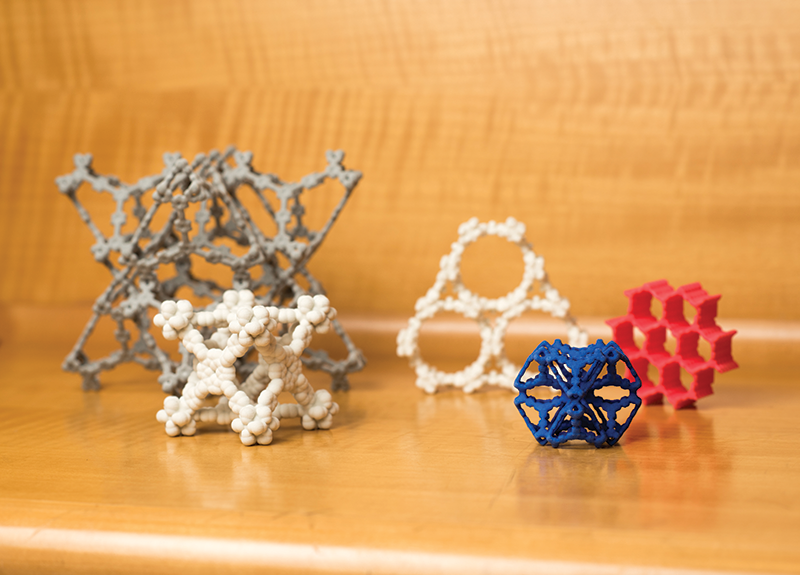

NuMat

Nanotech startup NuMat has developed a more effective method for storing and separating gases—one that eventually could work for vehicles that run on hydrogen gas. NuMat modifies the interiors of cylinders and other gas equipment with nanomaterials called metal-organic frameworks (MOFs) that can be programmed to selectively interact with targeted gases and chemicals. MOFs have immense storage capacity, which makes them incredibly valuable in fuel and gas storage.

“You can think of NuMat’s technology like a bath sponge,” says Omar Farha, president and chief scientific officer. But instead of holding water, NuMat’s MOFs store gases and chemicals. Farha continues, “In the long term, we’re going after applications such as CO2 capture, hydrogen storage for vehicles, natural gas storage for vehicles, and separation applications.”

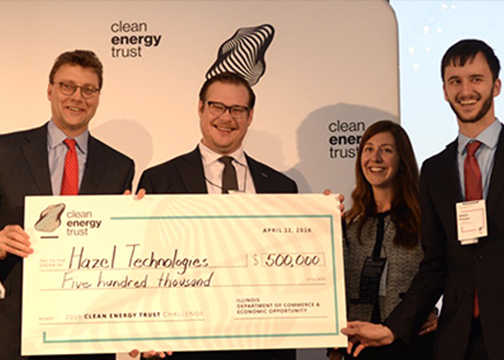

In September 2016, NuMat announced it had entered a partnership with The Linde Group, one of the world’s leading industrial gas and engineering companies. Linde will use NuMat’s innovations to create better gas storage solutions for its customers. NuMat also has a contract with the US Department of Defense to see how MOFs can scale. The startup has grown to 17 employees, Farha says, including engineers, chemists, and other experts with decades of experience in the industry. NuMat has won a slew of startup competitions, including those sponsored by Northwestern, the Clean Energy Trust, and the US Department of Energy.

Lilac Solutions

As the consumer demand for electronics and electric cars has accelerated, the global demand for lithium has also increased as manufacturers find new ways to make more efficient and long-lasting batteries. Tesla alone expects to produce 500,000 electric cars by 2020, and predictions are for a $1.7 billion global lithium market by 2019.

Lilac Solutions is working on a new way to extract lithium to make the process of mining this highly prized element more efficient and cost effective, according to Lilac’s co-founder David Snydacker (McC ’16). But the challenge, he acknowledges, is extracting enough lithium at scale to keep up with the increasing demand created by every phone, tablet, and other device destined to hit the market in years to come.

Today, most lithium is extracted from salt brines in South America using a process that requires expensive evaporation ponds, results in toxic salt piles from the residual salt collected, and takes up to two years to complete. Even then, this expensive and time-consuming process recovers only 50 percent of the lithium that’s available in the brine.

Lilac’s method uses ion exchange beads to directly remove and retain only the lithium from the brine while allowing elements like sodium and magnesium to pass through without being collected. What’s more, it can also be done in as little as one day, not two years, Snydacker says.

Lilac, which is still refining its technology, has already filed for three patents and is designing mining equipment that it plans to sell to lithium miners. “The lithium producers are very excited to have new technologies coming into their space,” Snydacker says. “With our technology we eliminate large evaporation ponds and truckloads of chemicals … and we can get more lithium from the same amount of brine.”

Hazel Technologies

Two-year-old startup Hazel Technologies wants to make your produce last longer. The startup has created an insert for placement inside produce packaging that can extend the shelf life of the fruit or vegetables up to 50 percent by distributing ethylene inhibitors. Similar in size to a packet of sugar, the insert is being used today by growers and shippers to help make their items last longer, improving profitability.

“Giving customers another five days [of shelf life] means it can be attractive in the store longer and less likely to go bad en route,” says Hazel’s co-founder Adam Preslar (McC ’15). “A product that can increase life and quality will translate to more sales and satisfied customers.”

The startup is funded in part though a United States Department of Agriculture grant and has raised more than $1 million in funding.

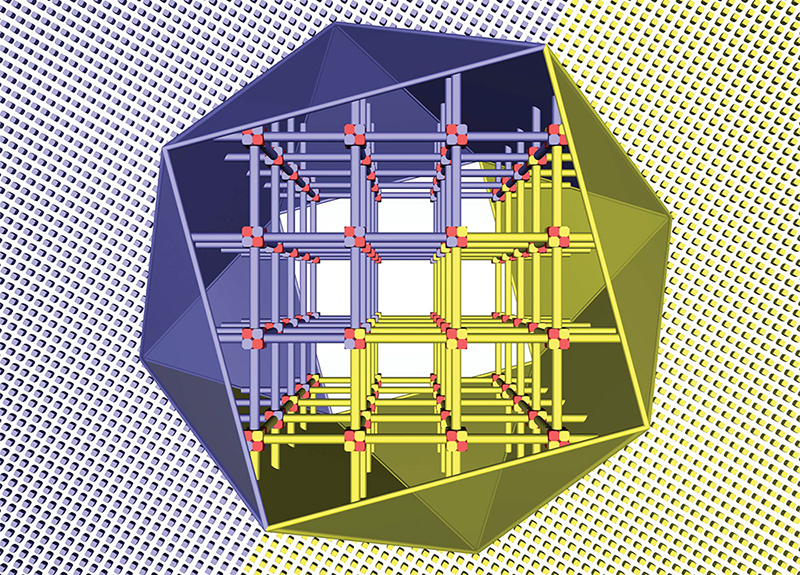

SiNode Systems

SiNode Systems is developing materials for the next generation of lithium-ion batteries. The company’s technology—silicon-graphene anodes—has potential uses in a wide variety of industries from consumer electronics to electric vehicles.

SiNode Systems’ materials are used inside a battery to make it last longer and charge faster, founder Samir Mayekar (KSM ’13) says. The technology can charge a cellphone battery in fewer than 15 minutes, the company claims.

The startup has ambitions to change the landscape for lithium-ion batteries. It has already caught the eye of Ford, GM, and Fiat Chrysler, which announced a $4 million deal with SiNode to develop high-energy anode materials to power next-gen electric cars.

“Anytime you have the end OEMs working with you, it’s a good sign,” Mayekar says. He also notes that SiNode is “on the cusp of commercialization,” and the startup has several customers with whom it’s working to bring product to market.

Ultimately the company plans to sell its technology to battery makers—like Elon Musk’s Gigafactory battery plant, for example—with the long-term goal of developing products to meet the electric vehicle market. In the short term, Mayekar says his technology could be used to help power small consumer gadgets as well as drones, tablets, and smartphones.