Revitalizing US infrastructure with data-driven foresight, bold leadership, and strategic investment

The end of World War II marked the beginning of a golden age for American infrastructure. Significant investment in roads, bridges, water networks, power grids, and railroads created the interconnected transport and service networks upon which our modern economy depends.

Once a global standard for excellence, these critical structures are beginning to reach the end of their useful lives. The American Society of Civil Engineers (ASCE) recently gave US infrastructure a grade of D+ (i.e., “strong risk of failure”) and estimated the need for $3.6 trillion in investment over the next 15 years. As these interdependent systems begin to falter, so too does our economic competitiveness. Since the early 1990s, Chinese infrastructure investment has outpaced that of the United States by nearly 350 percent, while US spending continues to decline.

Fortunately, there is no shortage of ideas to revitalize—and in many cases, revolutionize—the nation’s infrastructure. But building a better future will require leadership both locally and nationally.

The Future of the Built Environment

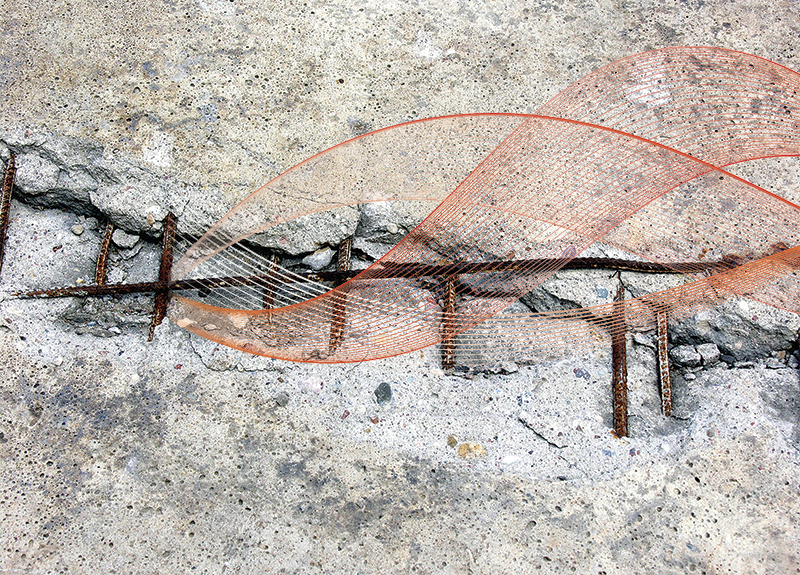

Dams, roads, sewer systems, airports, bridges, power plants, tunnels. Nearly all of our built infrastructure is comprised of concrete. And with good reason. It’s cheap and simple to produce, and it provides durability and strength like few other construction materials, but it doesn’t last forever. From real-time data to genetically engineered bacteria, innovators are reimagining the ways in which we use, manage, and repair the literal building blocks of modern society.

In terms of its compression—the ability to hold things up—concrete is particularly strong and effective. However, when it comes to tension—the ability to withstand flexing and being pulled apart— concrete is shockingly fragile.

“To combat this,” says Gianluca Cusatis, associate professor of civil and environmental engineering at Northwestern, “most of the material used in infrastructure projects is reinforced concrete, which involves casting wet concrete around steel reinforcing bars, also known as rebar. Many people don’t realize that it’s the bars—not the concrete itself—that are the primary element holding many structures together.” Corrosion of these reinforcements ultimately causes structural failure. “Water is the biggest enemy of rebar,” says Cusatis.

“It carries corrosive chemicals like chlorides and sulfates through pores in the concrete to the steel elements. Anything that increases the ability of water to reach the steel reinforcements is a problem.”

Even though concrete is fundamental to the most critical elements of our built environment, protocols for monitoring its safety and functionality are often deficient. “Currently, we rely on experts to go out and survey infrastructure mostly by hand. The visits are often infrequent—especially in remote areas—and the assessments aren’t very scientific,” Cusatis says.

He and other leaders in the field advocate the use of real-time sensors and mathematical models that predict when and where structures should be repaired. “Because we’re not investing enough resources to repair all of our aging infrastructure at once, it becomes a question of priorities,” says Cusatis. “The models we’re developing at Northwestern are powerful tools that rely on informed forecasts rather than perceptions. Decision makers will know if they need to invest in this bridge today, or if they can wait a few years.”

But real-time sensors and predictive models are just the beginning. Experts are exploring a wide array of new technologies aimed at improving our built environment.

Remote control aerial drones with high-quality cameras are working their way into the infrastructure management tool kit. Drone technology could greatly improve the efficiency and frequency of infrastructure inspection by enabling engineers to examine widely dispersed or inaccessible areas in a relatively short amount of time.

“People are also exploring ways to make concrete more durable,” Cusatis says. “Researchers at Northwestern and elsewhere are developing ultra-high-performance materials that weave reinforcement fibers into the concrete mixture. Other research includes self-healing materials, where researchers put dormant bacteria into the pores of the concrete. When the bacteria come in contact with water, they become activated and produce calcium carbonate, which fills in the cracks. From big data to bacteria, it’s a very interesting time to be working in this field.”

The Future of Water Infrastructure

We don’t create water. We simply capture and purify it. Prioritizing clean drinking water and efficient wastewater services is vital for sustaining public health, supporting the economy, and protecting the environment. But public investment in water infrastructure and management remains shockingly low. ASCE estimates the need for $12 billion annually to reach a state of “adequate” by 2020. Likely solutions not only involve deploying innovative technologies, but also envisioning new ways to repurpose this finite resource.

Nearly all the water infrastructure in our major cities is designed for purifying and managing one thing: drinking water. Yet, less than eight percent of water in the United States is actually used for drinking purposes, according to a recent US Geological Survey analysis.

“The management of drinking water is incredibly costly, time- consuming, and energy-intensive,” says Aaron Packman, professor of civil and environmental engineering and director of Northwestern’s Center for Water Research. “The current system is very inefficient.”

Packman and others advocate new types of water systems in the United States that reuse wastewater, mostly for industrial and commercial purposes. Matching industries with sources of wastewater and building the infrastructure and control mechanisms to facilitate the economical reuse could lead to big savings for businesses, end-use customers, and the environment.

“While it’s certainly important for drinking water to meet health and safety requirements, many water-intensive industrial processes don’t require the same standards,” Packman says. He points to the electric power sector, which annually uses almost half of the nation’s water supply to drive turbines to produce electricity. That’s triple the amount of water that passes over Niagara Falls in a year.

Packman is working diligently to turn the US wastewater recycling infrastructure into a reality. His colleague Harold Kung, professor of chemical and biological engineering at Northwestern, is developing an innovative technology that may help.

If an industrial entity wants to repurpose untreated wastewater, it needs to push it through a filtration system. The problem? Microorganisms. As water is pushed through, they stick to the filter, multiply, form colonies, and begin to clog it.

“The blockages mean that you need increasingly large amounts of energy to force water through the clogged filter,” Kung says.

“Eventually, the pressure becomes too high and breaks the apparatus, or you need to clean or replace it. The process becomes incredibly time-consuming and costly.”

To solve this problem, Kung is creating a new material to use in industrial wastewater filtration systems.

“I’m experimenting with a catalyst that will utilize air particles and organic material that are dissolved in the wastewater to create reactive oxygen molecules—something like hydrogen peroxide,” says Kung. “As the wastewater comes into contact with the catalyst, this species is generated, and it kills the bacteria. No bacteria ultimately means no blockages. It will save water, energy, time, and money.”

The Future of Mobility

When it comes to transportation in the United States, trucks and cars reign supreme. Even though private motor vehicles account for more than 90 percent of the country’s daily passenger trips, the nation’s roads and highways are alarmingly inefficient, not because of the system’s design, but because of the way people use it. One solution involves turning automobiles into interconnected, automated computers on wheels.

The 2015 Annual Urban Mobility Scorecard, an extensive report from the Texas A&M Transportation Institute, examined traffic trends and their economic impacts. It revealed that travel delays due to congestion kept drivers stuck in their cars for nearly seven billion extra hours and caused travelers to waste more than three billion gallons of fuel. The annual nationwide price tag of the delays and extra fuel amounted to $160 billion, or $960 per commuter.

“Facilitating the easy, cost-effective flow of goods and people is one of the most important drivers of economic development,” says Joseph Schofer, professor of civil and environmental engineering at Northwestern. “Our transportation systems are primarily about creating, attracting, and sustaining jobs.”

While spending on transportation infrastructure stimulates temporary job growth in construction, access and mobility create lasting value. Well-connected areas become more economically competitive, attracting and retaining business opportunities. When mobility is constricted, economic opportunities wither.

“The average throughput of traffic on a freeway is 1,800 to 2,000 vehicles per hour per lane,” says Hani Mahmassani, professor of civil and environmental engineering and director of the Northwestern University Transportation Center. “But this flow breaks down over time as vehicles interact—people slow down, change lanes, and so on. The breakdown leads to an actual throughput of about 1,300 to 1,400 vehicles, meaning we’re losing about one-third of the capacity for which these systems were designed.”

Technology can improve this flow breakdown by removing the human elements. Enter self-driving vehicles, big data, and dynamic pricing.

“Reaction times with autonomous vehicles are quicker and less abrupt, which greatly improves the traffic flow efficiency,” Mahmassani says. “The first autonomous vehicles will likely be deployed as fleets like Uber, Lyft, and Zipcar rather than through individual purchase. This has to do with economies of scale and the gradual adoption of the new technology.”

As digitization of automobiles becomes more pervasive, the capabilities of autonomous vehicles increase. Not only will automobiles drive themselves, they’ll also collect and transmit vast amounts of data, communicating with us and with one another. Among other things, this could greatly improve the efficiency of roads. As congestion begins to spike on a particular highway, vehicles throughout the area could be alerted and automatically redirected to more efficient routes, easing the flow on the entire system.

The data revolution also has implications for the way we pay for transportation infrastructure. The bulk of public spending on roads and highways currently comes from motor fuel taxes. But the national tax has not been raised since 1993, when it was at 18.4 cents per gallon and gas prices hovered around one dollar per gallon. As big data enters the automotive sector, we may start paying for the time and routes we take rather than for the gallons of gas we consume, what’s known as “congestion pricing.”

“Under this pricing system, a device in your car would track your use of various roads,” Schofer says. “At the end of the month, you would receive a bill reflecting how many miles you drove and the level of congestion on the roads you used. The idea isn’t new, but now we have the technology to do it in an easy, equitable way.”

A 1995 pilot program on State Route 91 in Orange County, California— one of the most heavily congested freeway corridors in the state at the time—became the first practical application of variable congestion pricing in the United States. The pricing regime, which charges drivers between $1.55 and $10.45 for a ten-mile trip depending on the time of day and day of the week, greatly reduces delays, accidents, and greenhouse gas emissions associated with idling vehicles.

Revenue collected from the program—approximately $40 million per year—also funds highway maintenance and expansion. Chicago drivers can expect to see similarly priced express lanes on the city’s I-55 Stevenson Expressway in the coming years.

The Greening of Infrastructure

Population growth is ballooning in cities all over the world. In fact, it’s getting ready to pop. By 2030, global population is expected to increase by 1.7 billion people, nearly all of whom are predicted to reside in urban centers.

Such unprecedented urban growth creates new challenges, particularly the strain it’s putting on overloaded and aging infrastructure. As policy makers strive to address the problems of overburdened built environments, they’re looking to an unexpected source for inspiration: Mother Nature.

The Nature Conservancy (TNC), a science-based advocacy organization that works in land and water conservation in urban and rural communities throughout the world, has been leveraging lessons from nature since the 1950s. At the end of 2016, the organization’s notion of “nature as infrastructure” reached a whole new level through a partnership with China, the most rapidly urbanizing country in the world.

Over the past 40 years, China has seen half a billion people moving from the countryside to urban areas, perhaps the largest and most rapid migration in human history. In an effort to keep pace with intensifying urbanization, the country is spending more on national infra- structure than North America, Western Europe, and Latin America combined. One of those investments, the foundation of TNC’s partnership, involves China’s ambitious Sponge Cities Program.

“The concept of using natural infrastructure isn’t new,” says Bob Moseley, Director of TNC’s Asia Pacific Cities Program and advisor for the organization’s efforts in China. “But no one has ever deployed these interventions at such a large scale and in such a methodical way.”

Sponge Cities is a stormwater absorption program initiated by China’s central government in 2014 to alleviate the escalating problem of urban flooding. In July 2016 alone, the nation’s overburdened stormwater infrastructure and poor water management led to 150 deaths in central and northern regions of the country.

“Through Sponge Cities, China is looking to deploy unconventional, natural infrastructure technologies to soak up and divert rainfall rather than relying on overburdened gutters, drains, and rivers,” Moseley says. “They’re looking at using permeable materials and green spaces to soak up rainfall instead of simply relying on solid concrete to divert or contain it.”

TNC is working in the city of Shenzhen to do just that. Representative of China as a whole, the population of Shenzhen grew from just 30,000 people in the 1970s to more than 11 million today—about the same population as the entire state of Ohio.

“TNC, in collaboration with the government in Shenzhen and other partner institutions, will analyze the ecological, hydrological, and social aspects of the landscape to figure out where to get the biggest impact,” says Moseley. “Everything from soil types to socioeconomic equity will affect the location and types of solutions we deploy.”

In addition to deploying natural solutions, TNC is helping China explore innovative public policy, financing, and management structures for similar types of projects. “China’s central government has left a lot of room for innovation in the deployment of Sponge Cities, which is rare in my experience,” says Moseley. “For example, China has shown interest in a market-based stormwater credit trading system that TNC helped establish in Washington, DC, to prevent water pollution.”

While concrete and steel will undoubtedly play an important role in infrastructure for the foreseeable future, China’s large-scale experiment with Sponge Cities has Moseley optimistic that an increasingly large portion of global infrastructure will be green.

Resilient Reinvention

Regardless of the future design or composition of our national infrastructure, it’s clear that imagination and reinvention are crucial. A decisive investment in our infrastructure is a decisive investment in our legacy of socioeconomic resilience and the economic vitality of our communities.