For the first time ever, NuMat Technologies is taking its gas capture, separation, and storage technology out of the laboratory and into the commercial marketplace. The Northwestern spinout company’s decision to release its first commercialized product comes on the heels of its recently announced partnership with Linde Group, the second-largest gas company in the world.

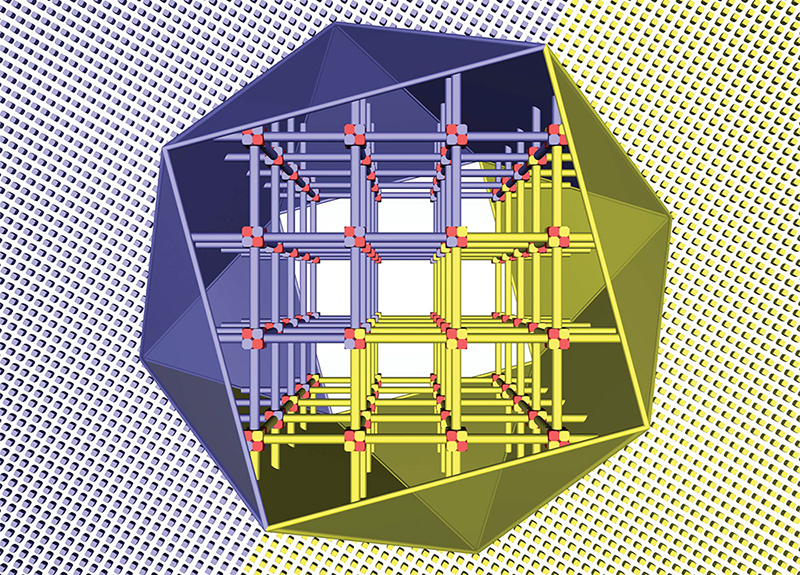

NuMat specializes in developing an emerging class of nanomaterials known as metal organic frameworks (MOF). The materials’ sponge-like, crystalline structures and extremely high internal surface areas make them ideal for attracting and storing gas molecules, which tend to “stick” to surfaces.

NuMat currently has the second-largest production of MOFs behind Baden Aniline and Soda Factory (BASF), a large chemical company based in Germany. While most academic laboratories are only able to produce a few milligrams of a MOF, NuMat is now producing hundreds of kilos—generally in the span of a few hours.

“There has been significant interest in MOF commercialization for some time, but beyond work in academia and the marketing efforts of BASF, there has yet to be a true MOF-enabled product on the market,” says NuMat co-founder and CEO Ben Hernandez (McC ’06 and KSM/Law ’13). “NuMat is preparing for a global launch of what we believe will be the first-ever commercialized product of this kind—a significant milestone for the field.”

For this first commercial application, NuMat will focus on using MOFs to capture toxic gases produced in the electronics sector. Specifically, NuMat is designing MOFs for boron trifluoride, arsine, and phosphine gases, which are used in semiconductors for microchips that go into cameras, smart phones, computers, and similar devices. By capturing these noxious gases in sealed canisters filled with MOFs, NuMat will be able to store them more efficiently and safely than traditional high-pressure gas compression methods.

“Using MOFs allows us to store gases sub-atmospherically, meaning the pressure inside the canister is actually lower than the pressure outside,” says Omar Farha, chemist and research professor at Northwestern University and co-founder and CSO of NuMat. “In the unlikely event that there’s a leak in the canister, outside air will rush in rather than toxic gases leaking out.”

The use of MOFs also allows companies to avoid the compression process, which is incredibly energy intensive and often costly, says Farha.

While NuMat’s first commercial application will target the electronics sector, the technology has much broader capabilities. Indicative of this fact is NuMat’s new partnership with Linde Group, a company that supplies gases to a wide variety of large industrial users. In its role, NuMat will be developing MOF-enabled products for gas separation and storage in order to make Linde’s systems better, more compact, and more efficient.

“As a global organization, Linde is looking to maintain an advantaged technological position in the marketplace,” Hernandez says. “As a total-solutions provider focused on developing fully integrated commercial systems and innovating on material design, NuMat is well positioned to support Linde in solving its toughest challenges. This partnership model is one component of our global strategy, which we’re working to replicate elsewhere.”

MOF commercialization for the electronics industry and its partnership with Linde are just the beginning. As it wades into uncharted waters in the gas separation and storage industry, NuMat is thinking strategically about its vision for the future.

“The NuMat team is incredibly excited to use everything we learn from the commercialization process to solve even more difficult problems,” says Farha. “We’re not just applying this technology for incremental change. We want our MOF systems to completely transform the way certain industries function.”

Image credit: RSC Publishing