Northwestern researchers outline a vision for the future

On October 22, Julia Kalow, assistant professor of chemistry at Northwestern, and Jeffrey Richards, assistant professor of chemical and biological engineering at Northwestern, led a virtual seminar titled “Chemistry and Engineering Approaches to Close the Loop on Elastomers.” The presentation on the recyclability of thermosets and elastomers was part of a webinar series hosted by the Program on Plastics, Ecosystems, and Public Health (PEPH) at the Institute for Sustainability and Energy at Northwestern (ISEN). This exclusive event was attended by panelists from academic, corporate, nonprofit, and industry sectors.

Thermosets and elastomers are polymeric materials that are especially valued for their durability and elasticity. These characteristics have made them an integral part of medical, construction, and transportation industries.

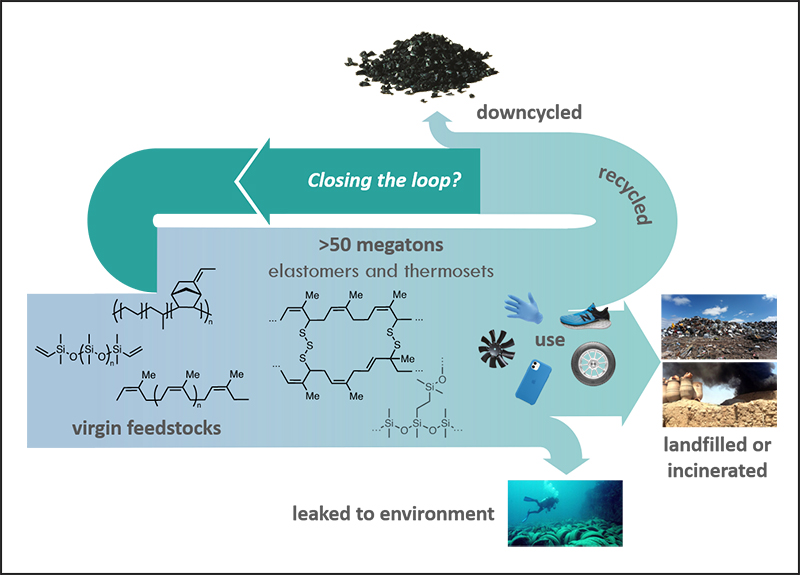

The covalent links in these polymers can prevent thermosets and elastomers from being recycled through conventional methods. Covalent links, or covalent bonds, are a type of bond where two atoms share an electron pair. This electron sharing is what makes networks based on covalent bonds so strong. Because elastomers and thermosets are held together by such strong covalent links, when these materials are broken down, the bonds cannot be reformed, which prevents thermosets and elastomers from being recycled or reprocessed for reuse. As a result, they end up in landfills or even potentially leaking into the environment.

In a collaborative effort to find solutions to repairing and reprocessing these polymeric materials, Kalow discussed approaching this problem from a chemistry point of view while Richards discussed taking an engineering approach. Taking a chemistry approach, the Kalow lab conducted research on developing dynamic covalent bonds of the polymers as well as considering their structure-property relationships. From an engineering and industry perspective, the Richards lab focused on researching how these materials are altered through reprocessing.

The Kalow lab directed research on applying the concept of vitrimers to silicone elastomers. Elastomers are soft but stretchy materials that include rubber; silicone elastomers are commonly used in sealants, medical devices, and cookware. Vitrimers are ideal candidates for reprocessing, as their dynamic covalent bonds allow them to be remolded and reprocessed with applied heat as opposed to traditional elastomers and thermosets, which are difficult to reprocess in the same way. The dynamic covalent bonds found in vitrimers can undergo reversible reactions and bond exchanging, thus enabling recycling. These exchange processes occur without breaking apart the network, which allows them to exhibit solvent and temperature resistance so that their original properties are not permanently lost through reprocessing.

Following this concept, the Kalow lab’s research involved designing a material that is elastic at room temperature to retain its properties that can additionally become viscoelastic and moldable at higher temperatures to enable recyclability.

“My group is really focused on the more fundamental side of this. While we’re not at the point of making competitive materials, we hope to identify design parameters and design rules that might tell you how to tune the chemistries of the structures of these vitrimers to make them more competitive while maintaining recyclability,” says Kalow.

Richards’ research focused on the changes that elastomers and thermosets exhibit after experiencing large deformations akin to those that occur during the recycling process. The Richards Lab addresses how we can anticipate the impact of recycling processes on the mechanical properties and lifetime of these materials. Factors contributing to property change include the rate and magnitude of the non-linear deformation. Further, the extent of degradation depends on the intrinsic material chemistry and specific processing conditions. All of these factors must be considered and engineered when considering the appropriate recycling process.

“We have highlighted three different mechanisms by which the material relaxes stress and acquires strain irrecoverably. Understanding the balance of those different types of mechanisms is critical to identifying the regimes where recyclability is feasible,” states Richards, suggesting that a clearer identification of these regimes will help to find ways to increase the recycling value of non-metallic materials rather than having them considered as waste products during the sorting component of the recycling process.

The Richards lab is currently pursuing more research into the degradation that can occur in recyclable plastic materials even in their most optimal recycling conditions.

Questions from panelists suggested that the application of the dynamic covalent bonds in vitrimers to elastomers is not yet a fully accessible concept for commercialization, but the research conducted by Kalow and Richards proves to be a promising step forward into closing the loop on the recyclability of elastomers and thermosets that can contribute to the reduction of plastic materials in landfills and decrease the need for nonrenewable feedstocks or fuel to power industrial processes. The Q&A portion of the webinar suggested an interest in further research into a method of directly transforming materials into vitrimers rather than going through the process of re-synthesis and redesigning materials to exhibit vitrimer properties, which can be costly. Other concerns suggested an interest in the environmental impact of reprocessing and the potential for new pollutants arising from vitrimer-like materials containing supplemental fillers and how environmental conditions may affect the performance of polymeric materials. Overall, these thought-provoking questions reflected an enthusiastic response towards the topic of vitrimerization and its potential for commercialization.

Such interesting and informational dialogues will continue to be hosted by PEPH, a multidisciplinary science initiative that examines the cost of the plastic revolution with priorities on the lifecycle of plastics on the environment and public health and discovering alternative, environmentally friendly materials. In doing so, ISEN assembles experts not only from Northwestern, but from academic, civic, NGO, and industrial partner institutions.